Nanocomposite Ceramic Separator:

<1% heat shrinkage for increased battery safety

Failure of the separator may cause a direct short between electrodes, leading to catastrophic thermal runaway. The video below demonstrates the difference in a nail penetration test of two identical cells, one using a patented NPORE® separator, the other a standard PE separator.

NPORE® Ceramic Separators

NPORE® is the world’s first flexible, freestanding ceramic nanoporous membrane separator for lithium ion batteries. NPORE® separators eliminate the use of plastic substrate, and provide superior functionality and outstanding heat resistance for current and next generation lithium ion batteries. NPORE® features include:

Thermal Stability

- Best in class dimensional stability

- 5x higher thermal conductivity vs. plastic separators

- Flame resistant

Electrochemical Performance

- Superior abuse resistance

- Rapid wet out with battery electrolytes

- 3x greater compression resistance vs. plastic separators

- Excellent electrolyte conductivity

- Uniform and narrow pore size distribution

Electrode Coated Separator (NPORE® ECS)

A Simpler and Faster Battery Assembly Process

Electrode Coated Separator technology, developed with funding by the DOE, aims to reduce the cost of manufacturing lithium ion batteries and the inactive components cost by 20-40%, while improving battery safety, lifetime, and energy and power density. NPORE® ECS incorporates new inactive components of separator, current collectors, and termination materials, and utilizes a simpler and faster battery assembly process.

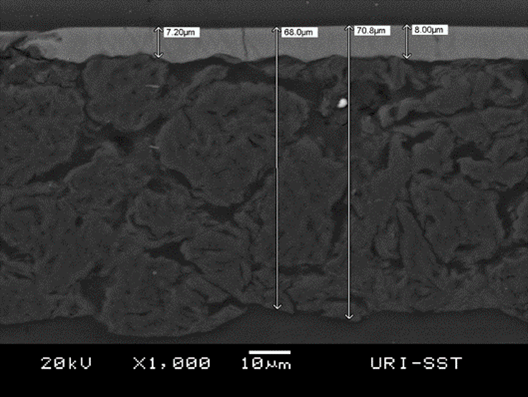

- The 8 micron thick ceramic separator reduces inactive component cost >20% and improves safety and cycle life

- Developing new processes for metal current collection layers and for tabbing and termination

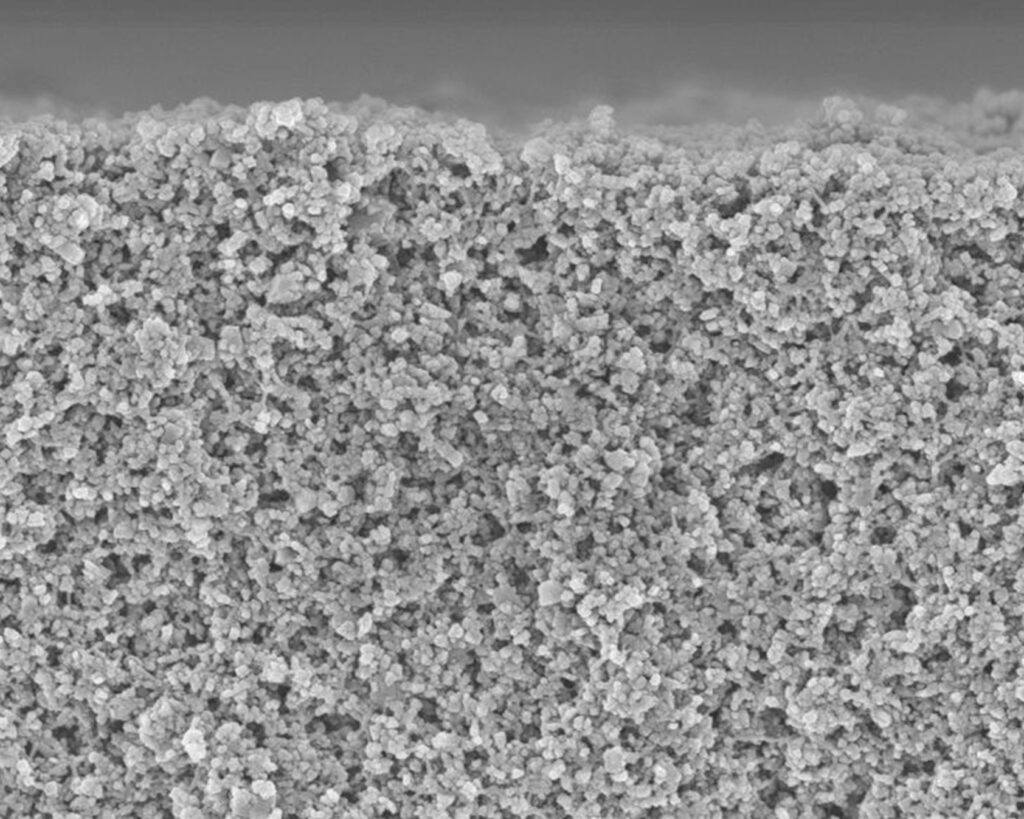

Patented Nanoporous Membrane Technology

Our NANOPORE®nanoporous membrane technology platform offers customizable permeable layers with distinctive features, including highly uniform pore sizes, which are extremely desirable for a number of high-tech applications, including energy storage and filtration. Our patented NPORE® battery separator technology provides strength and flexibility with the added benefit of high-temperature stability to improve battery safety. Our battery innovations are covered by a large portfolio of pending and issued patents worldwide.

Properties

- Highly flexible and strong nanocomposite membranes

- Exceptional heat stability, with no shrinkage above 200◦C

- Uniform pore sizes with narrow pore size distribution

- Highly customizable nanopore sizes, ranging from less than 10 microns to 100 microns

Applications

- Battery separators for lithium batteries

- Electrode-coated separators: a streamlined, advanced manufacturing process for lithium batteries

- Filtration membranes

- Medical metamaterial devices