Lithium-Ion Battery Safety and Sustainability – Essential to the Clean Energy Transition

Long-lasting, fast-charging, high-energy-density lithium-ion batteries are essential ingredients to modern life, powering billions of internet-connected mobile devices and a rapidly growing e-mobility segment, from e-bikes to passenger EVs, electric busses and trucks. The transition to clean renewable energy will require a massive increase in battery usage, for electric transportation, as well as grid storage, to balance the output from intermittent wind and solar resources. However, to support this growth, the battery industry faces two major challenges: safety and sustainability.

Battery Safety – What causes battery fires?

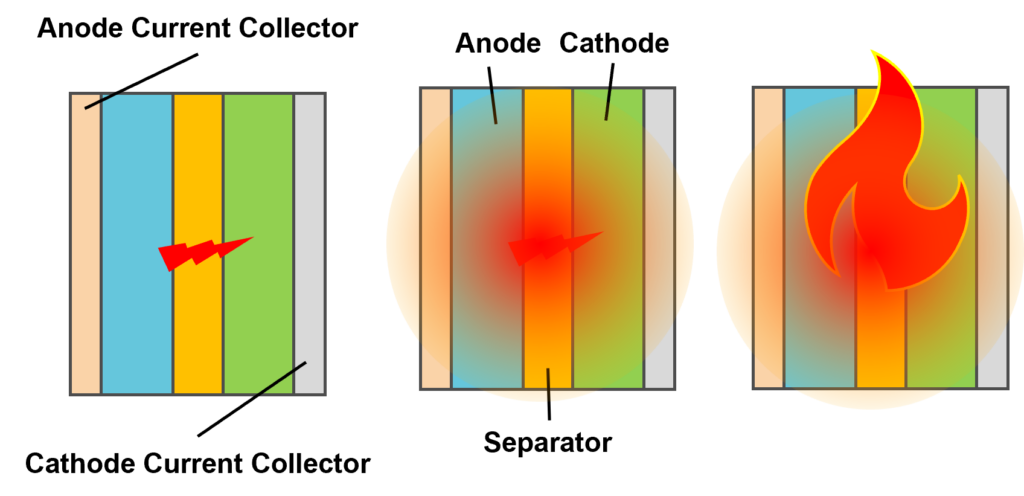

In normal operation (charging and discharging), lithium-ions pass between the two battery electrodes (the anode and cathode) across a thin, porous membrane (the separator), and current travels along two metal foils (the anode and cathode current collectors). Sometimes, a short circuit occurs between the two electrodes, which may result from a manufacturing defect, stress from rapid/overcharging, or an external impact/penetration. When this happens, current rushes into the site of the short, rising temperature causes the standard separator to shrink, enlarging the hole, more current pours in, and this runaway reaction ignites the electrolyte, causing a very intense, hard to extinguish fire.

META Offers Two Ways to Inhibit Thermal Runaway and Help Prevent Battery Fires

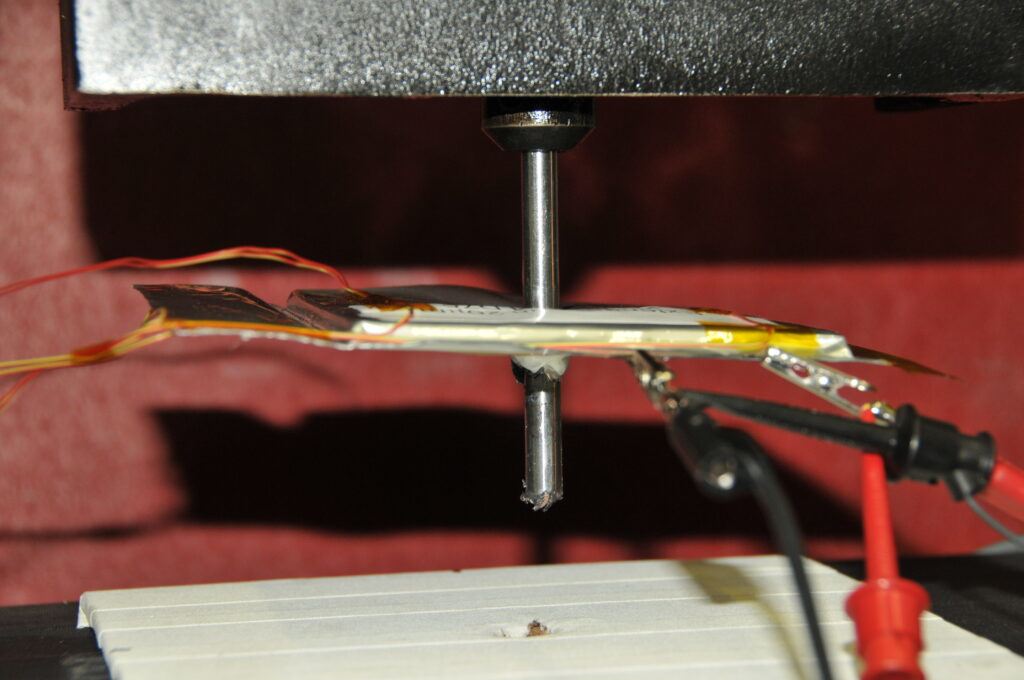

NPORE® nanoporous ceramic separators feature <1% heat shrinkage. As shown in the pictures and videos below, this helps prevent a short circuit between the electrodes from growing into a thermal runaway and causing a battery fire.

NCORE™ polymer composite current collectors replace the standard solid metal foils. If there is excess current at the location of a short, a plastic inner layer melts, acting like a fuse, to break the circuit and help stop a thermal runaway.

The Clean Energy Transition Can’t Succeed without Sustainable Battery Supply Chains

Driven by the energy transition, demand for copper and other critical materials is expected to outstrip supply, pushing up prices and requiring massive new mining projects with negative environmental impacts. Economical and sustainable solutions are needed. NCORE™ current collectors, made with proprietary PLASMAfusion® vacuum deposition technology, are designed to eliminate more than 90% of the copper used in anode current collectors, which make up 10% of the weight of a typical lithium-ion battery. This results in a lighter, more efficient battery, enabling electric vehicles to travel farther on each charge, and helps to make the battery supply chain more sustainable.

Enhancing Performance and Safety for EVs

Electric vehicle consumers desire increased range and fast charging to get back on the road quickly. Storing more energy relative to weight and volume and accepting higher charge rates increase the requirements for material performance, stability, and safety. Wider EV adoption demands improved material utilization along the supply chain.

META is developing new battery materials and manufacturing techniques to address all these challenges. NCORE™ polymer composite current collectors, made with proprietary PLASMAfusion® high-speed vacuum coating technology, significantly reduce weight, while adding a fuse-like safety feature. NPORE® ceramic separators feature <1% heat shrinkage for increased safety and offer superior electrochemical performance.

META® Battery Safety Solutions NCORE™ and NPORE®

NCORE™ Current Collectors: Reduced Weight, Enhanced Safety

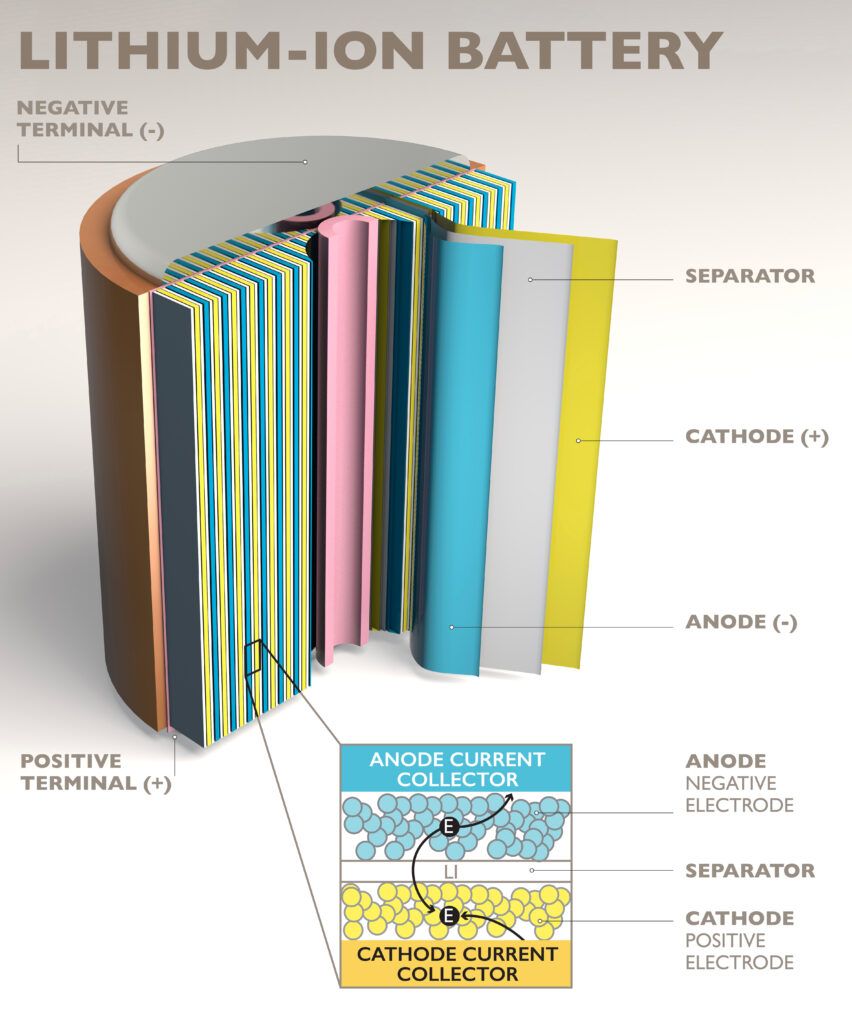

Copper foil is over 10% of the weight of a typical battery cell

Current collectors are essential components of lithium-ion batteries, consisting of aluminum (Al) and copper (Cu) foils for the cathode and anode, respectively. Collectively, current collectors account for about 15% of the total battery cell mass and do not actively contribute to battery capacity. Al has a low density of 2.70 g/cm3 while Cu is much heavier at 8.96 g/cm3 such that Cu foil current collectors account for more than 10% of the weight of a typical Li-ion battery.

Plastic substrate acts as a fuse to impede thermal runaway

A PET/PEN plastic substrate, coated with thin layers (150-250nm) of Cu on each side and embedded metal bridges for through conductivity, promises the same functionality and cost as copper foil, while providing several benefits. Weight is reduced by ~85% and reduced thickness allows more active material, increasing energy and power density. In case of thermal runaway, the plastic melts, improving safety by retarding battery self-ignition. Lower copper content reduces the energy input to produce the battery and enhances recycling.

NPORE® Ceramic Separators: <1% heat shrinkage for increased battery safety

NPORE® separator prevents thermal runaway in nail penetration test

NPORE® is the world’s first flexible, freestanding ceramic nanoporous membrane separator for lithium ion batteries. NPORE® separators eliminate the use of plastic substrate, provide superior functionality and outstanding heat resistance for current and next generation lithium ion batteries.

NPORE® features include:

Thermal Stability

- Best in class dimensional stability

- 5x higher thermal conductivity vs. plastic separators

- Flame resistant

Electrochemical Performance

- Superior abuse resistance

- Rapid wet out with battery electrolytes

- 3x greater compression resistance vs. plastic separators

- Excellent electrolyte conductivity

- Uniform and narrow pore size distribution

Next-Generation, Smart Passive Components for Improved Li-Ion Battery Safety and Performance

Peiman Hosseini, PhD, Dmitry Yarmolich, PhD, Ben Sloan, and Steven Carlson, PhD.

The separator and the current collectors (CCs) are found in every lithium-ion battery (LIB). These passive components are a principal determinant of the safety, performance, longevity, weight, and volume of a cell, while not directly participating in the electrochemistry. Decreasing their weight or volume can directly improve the gravimetric or volumetric energy and power density of a cell. Here, we present a new approach to enhancing the safety and performance of LIBs of various sizes and chemistries that utilizes two next-generation, smart passive components, NCORE™, a metal–polymer composite CC, and NPORE®, a nanoporous ceramic separator.

NCORE™ is fabricated by coating a 6-μm-thick polymer substrate with a thin (250 nm) layer of copper (Cu) metal on each side. High-density Cu elements (bridges) are also embedded within the substrate in this metallization process. The resulting material exhibits increased conductivity in both in-plane and out-of-plane directions. Functioning as a smart fuse, NCORE™ prevents additional inrush current from triggering a thermal runaway that can potentially lead to a dangerous fire that is extremely difficult to extinguish in a cell when its internal temperature exceeds 250°C. Eliminating up to 90% of the Cu contained in a typical CC, NCORE™ reduces the weight of the battery and improves its performance and recyclability.

NPORE® is a proprietary, robust, nanoporous ceramic separator that is highly resistant to melting and shrinking. In the case of an internal short circuit between the electrodes, which may be caused by a dendrite or other defect, NPORE® does not shrink away from the location of the defect, inhibiting the heat caused by the short circuit from propagating a thermal runaway. The combination of NCORE™ and NPORE® offers an innovative safety solution for LIBs of a wide range of chemistries and form factors.